If you are new to using this equipment, you will be interested in this article. This guide will help you with how to use a Porter Cable air compressor, from installation to getting the most out of your equipment.

They are very easy to use with a variety of pneumatic tools. They are well-balanced in terms of weight and power. You don’t have to worry, you will have a large set of tools due to the standard fitting.

How to use a Porter Cable air compressor

It isn’t hard to use a Porter Cable air compressor, you’ll learn quickly.

First, make sure the hose is connected, then fill the water tank. Follow the instructions to avoid overfilling the tank of your Porter Cable air compressor and make a quick connect.

When the Porter Cable air compressor’s tank will be full. You can toggle the switch to the “on” position.

Now you can use your Porter Cable air compressor. Point your tool in the right direction and press the trigger.

When you have finished using your compressor, turn the switch to the “off” position.

Before disconnecting the hose from your Porter Cable air compressor, make sure the machine is turned off. Store the tool in a dry place when not in use.

Just use these rules with any Porter Cable air compressor and enjoy these safe and useful tools. Remember to store it in a dark place.

Wondering if there is any difference Pancake vs hotdog air compressor? See detailed review with Pros&Cons here.

Common mistakes in using Porter Cable air compressor

Although Porter Cable air compressors are the most popular tools on the market, many misuse them. Here are the most common mistakes.

1. Reading the manual

Take the time to read the manual if there is one. If there is none – go to your browser. The manufacturer always knows how best to use the device, and will definitely comment on it.

2. Filling the pump

Failure to prime the pump before use may damage the pump. Be sure to follow the instructions for filling the pump.

3. Air pressure is running out

The compressor will automatically shut off when it reaches a certain tension. Don’t try to save it by adding more air to the tank. This may damage the compressor and void the warranty.

4. Overloading electric circuit

The air compressor has a high amp draw and can overload the circuit if you’re not careful. Make sure you consult your manual to determine the proper electrical requirements for your model.

5. Drain the tank

If you do not drain the tank after use, moisture can build up and damage the compressor. Always drain the tank according to the instructions in the manual.

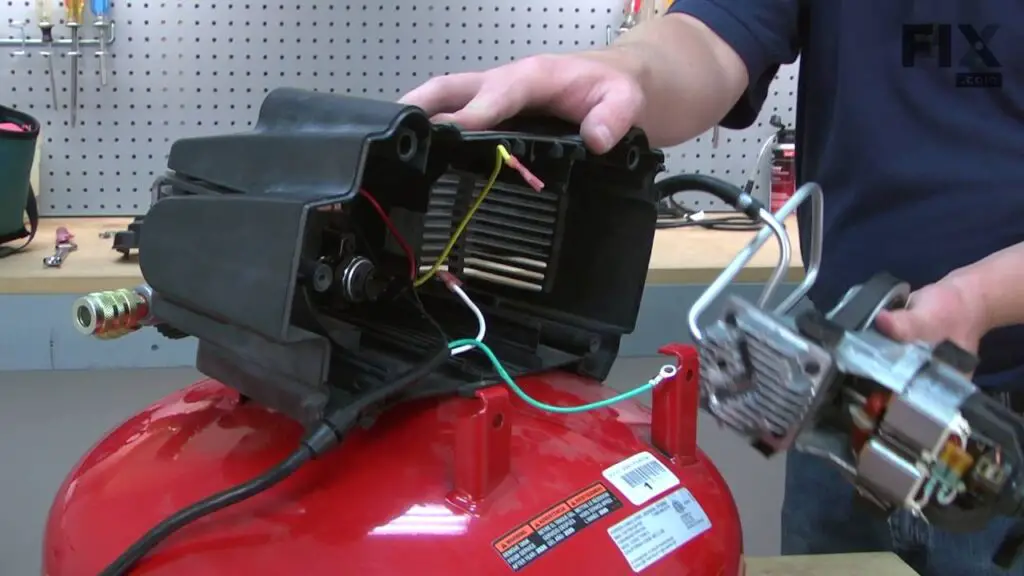

Cable connection to Porter Cable air compressor

There are two ways to attach the hose to air compressors. The first way is to screw in the hose or push the hose until it clicks. As mentioned before, don’t forget to read the manual of your porter cable compressor.

Porter Cable air compressor adjustment

You can adjust the fittings of the compressor by using the regulator knob. The handle is located on the porter cable itself. To increase turn the knob to the right, to decrease turn the knob to the left. The knob will make a quick connection.

Ensure safe operations

Don’t expose electrical parts of air compressors to water – it might cause a shock! Usually, operators keep electric drain valves away from humid and moist areas. When a gas-powered air compressor is active, refueling, and changing the oil can cause safety hazards. Instead, operate when the tool is cool.

Also, don’t forget to connect compressors to power outlets that have lightning arrestors. Keep fire extinguishers at strategic places near the machine, too. Don’t allow the inlet to exceed 90 PSI.

High air pressure can damage the performance of handy pneumatic tools. Knowing the requirement for equipment like tools, dryers, and air distribution systems is important.

To avoid damage to air hoses and tools, fine-tune their operations to meet the torque output of your compressor. Operators might need to cut the source of air and bleed the pressure from connecting hoses. When running, don’t block the vents or place your hands on hot parts of the machine.

If you need to know what size air compressor for plasma cutter, here you will read tips you were looking for.

Getting the most out of your Porter Cable air compressor – 4 hacking tips

Porter Cable compressors are the most sought-after options on the market, and for good reason. But like any tool, they need to be used correctly to extend their lifespan.

Tip 1. Choose the right air compressor size for your job

Porter Cable air compressors come in a variety of sizes, from small to large industrial. It’s very important to choose the size of the air compressor exactly for what you will be doing with it.

Tip 2. Explore the controls

Before using your Porter Cable air compressor, take the time to learn the controls. The control panel is simple, but it’s still worth reading the manual.

Tip 3. Using the right accessories

The Porter Cable air compressor comes with a variety of accessories to make your life easier. There are regulators, filters as well as hoses, and fittings of different sizes.

Tip 4. Proper storage of your air compressor

To prolong the life of your Porter Cable air compressor, you need to know how to store it. The basic rule is that the compressor should be stored in a dry, cool place. Make sure your tool is located out of direct sunlight.

If you are not going to use the air compressor for a very long time, it is recommended to add oil to the compressor to lubricate the seals.

Wonder what the best air compressor for soda blasting is, read the detailed review from a professional DIY expert.

FAQs

How do you use an air compressor for the first time?

To make sure that everything works, run a test run. To do this, turn the pressure supply switch to the “off” position, connect the power cord and start the compressor. The pressure gauge should rise slowly. Then disconnect the cord and switch off the machine.

How long does it take to fill a Porter Cable air compressor?

Most of the needs associated with a thirst for air can be easily met if the machine is stored at 6 gallons. At the same time, this air compressor takes about 3–4 minutes to reach full capacity.

How do you fill a Porter Cable air compressor?

Turn on the compressor and wait for the tank to fill. It’s ready to work when the pressure gauge needle in the tank stops moving forward and the engine stops. Find out what settings your instrument needs to work properly.

Usually, this information is printed on the underside of the tool, or you can always find it on the website of a company.

How do you use a Porter Cable air compressor for tires?

Attach the air compressor hose to the valve stem. Use a clamping chuck to attach the hose. Once everything is in order, turn on the compressor to inflate the tire. Fill the tire slowly to prevent the tire from pumping.

Summing up

So, we hope that we deliver all information you were searching for. And now you don’t worry about your tool. Follow all the instructions, make sure everything is connected correctly, and the device will be very helpful for you.

Always feel free to use the browser to find the website of the manufacturer for any specific details and leave a comment with your tips and tricks!