Sometimes your machine does not function when the compressor becomes broken. We usually face this problem with our air conditioner compressor during the hot summer days. But why does our compressor not operate? And if it happens, What To Do With Broken Air Compressor?

Air compressors can fail for a multitude of reasons. We generally face broken parts of the compressor or wear and tear over time. If a compressor is used in your everyday job, a malfunctioning air compressor might be a serious issue.

As a result, you must first determine the problem before deciding whether to fix it or replace it. Go and give a check for any clogged filters and damage. Keep in mind that some components of your compressed air system may be replaceable without replacing the air compressor itself. The majority of these issues can be resolved with appropriate air compressor troubleshooting. Or when you cannot troubleshoot, follow our given ideas on what you can do with the broken compressor.

How old is your air compressor

The air compressor typically lasts at least 15 years. The third character and the first two digits indicate the year of production. But how can you tell if and when the compressor has to be replaced? Let’s talk about this!

Always think about repairs before replacement! This is a good decision! Imagine your air compressor is new but somehow gets broken. However, you need to repair and upgrade the outdated compressor or tank.

When any internal components are damaged, it occasionally does not operate perfectly. Not to worry! If it needs fixing, we’ll do it. If your air compressor has been in use for fewer than 50,000 hours or less than ten years, you should repair it!

Looking for the best air compressor for spray painting? A detailed review is waiting for you here.

What causes air compressors to break

We found overheating to be the main culprit in most compressors. It typically occurs when the environment is very humid. One of the numerous problems, like the broken parts air leak, and oil leaks, could be the cause of an air compressor issue. Oftentimes, you might not have enough airflow or pressurization. When it malfunctions, we typically see several facts:

- The compressor is running; however, it does not work.

- The releasing airflow after the condenser is working is another indicator of an AC compressor failure. It happens because of the lackings of cooling power.

- Most often, you will notice the exterior air conditioning unit generating unusual noises that are louder than usual.

- It’s possible for your AC compressor to overheat and use too much power; trip your circuit breaker.

- A lack of pressure can completely ruin the machine sometimes. So check the present air demand if your air compressor only produces air pressure at low capacity.

- If your compressor is unable to unload, determine your compressor pressure button to make sure it operates properly at the right setting.

- Don’t forget to check the intake and solenoid valves’ capacity and performance.

- Your end-point systems may become poor if a small amount of oil reaches the separator. Additionally, you need to replace the oil separator.

- Your machine could frequently stop functioning if compressed air involves moisture. The water content should be kept as low as possible by a compressor machine.

- Also, maintain the overload relay.

Installing oil water separator on air compressor can be very easy with this step-by-step guide.

What can you do with a broken air tank

Determine the problem

This is the first thing that you need to do! Determine what the problem is with your compressor. Should you fix it or replace it? It’s better to have a look at the airline to fix the leaks or broken parts.

If multiple parts are not functioning, don’t be upset. You can fix it, but only after spending a little more time. But we often need to fix clogged air filters, broken air receivers, or low oil levels. However, identify the issue to solve the machine’s problem.

Keep the compressor as a backup

If your principal air compressor drops down, employing a backup compressor can help you reduce the duration of the interruption. For any future work, you can fix it and use it as a backup tank. Your compressor could occasionally be on the threshold of failure. Go and get it to keep it as a backup.

A backup compressor is phenomenal since we can never be sure when the new one will break. Any type of interruption can be avoided by using the backup plan. Additionally, the backup compressor will be available if and when your new compressor requires servicing. However, let’s have a look at the possible reasons why you should make a backup plan.

- Emergency work can be done with the help of a backup compressor or tank.

- A backup plan is quite budget-friendly, so keep it.

- It ensures that systems operate reliably.

- You Can Enjoy the Benefits of Remanufacturing with a Backup Compressor.

- Your cost of ownership can be lessened with a backup compressor.

You can repair the compressor

You can fix the machine with the help of technicians. However, if the compressor is properly damaged, get the compressor part. Because buying a new compressor is so expensive, you should opt for repair first. Later, you can replace individual components rather than buy the entire machine.

Why should you try to repair it? Let’s share some reasons that make you decide to repair or replace some parts but not the compressor machine.

- You should consider the cost and electricity costs. It is a powerful machine, so you need more electric power.

- Finding replacement parts for an older model compressor may be more challenging, time-consuming, and expensive. So make an effort to repair the damage or problems.

- You can upgrade it with a larger unit instead of replacing the machine.

How to fix a broken air compressor: 7 Awesome Tips

Tip 1. Check power supply

Check the compressor’s power supply to see if it’s properly connected and that the switch is turned on.

Tip 2. Press reset button

Try pressing the machine’s reset button if the machine still won’t turn on.

Tip 3. Check if there are any noises

Unusual noises coming from the compressor while it is operating could be a sign of issues with belts, flywheels, bearings, or crankcases. Fix it!

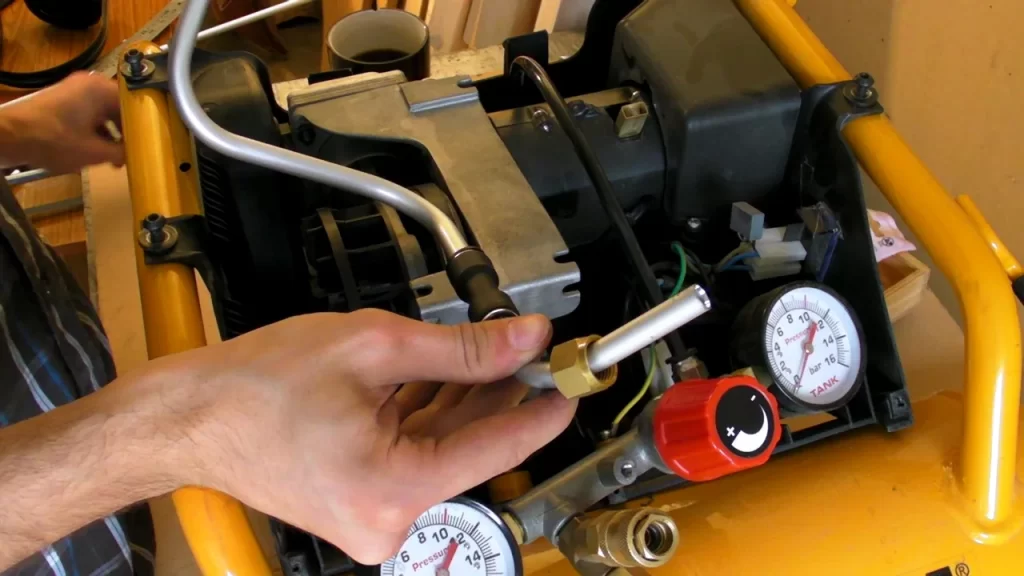

Tip 4. Check the airflow

The airflow can be changed. Check the compressor setting after turning the compressor on and off.

Tip 5. Use soapy water

Use soapy water around the fittings and make sure you check for bubble formation. If you notice bubbles, you probably have a leak. You must fix any leaks that are either within or outside the compressor.

Tip 6. Check oil consumption

Excessive oil consumption is a sign of loose bolts, insufficient air ventilation, and worn piston rings.

Tip 7. Ask technician for help

Additionally, excessively hot discharge air, belt deterioration, or frequently blown fuses might result in damaged compressor problems. Make sure you show it to the technician. All of the ideas are easy to solve and repair.

Wondering how long air compressor tanks last? In this related article, you will find the answer.

What to do with broken air compressor: 4 creative ways

The lifespan of a compressor typically lasts between 10 and 15 years. Usually, a machine begins to show some signs of breakdown and poor performance after ten years of use. But unfortunate issues may occur sometimes in a new compressor. At that moment, get a specialist to fix the compressor issue.

- You will notice the HVAC (heating, ventilation, and air conditioning) compressor breaks down often.

- The compressor may create higher energy bills, which is a sign that you need to replace it.

- Unusual noises, brief cycling, lowered cooling capacity, and some other problems indicate you need to change the machine.

- Sometimes the AC compressor shows it’s not cooling as effectively as it used to be. Or, it might give you warm air when running the ac.

1. Make the tank into a BBQ or Smoker

Hey, if you can’t decide what to do with the broken one, go make a working barbecue or smoker out of the compressor. Making recipes with an old or broken compressor is a fun DIY project. You can cook delicious meats like brisket, pig butt, or ribs.

2. Build a garden planter

How about making it a garden planter? If it’s completely broken, don’t leave it alone. Make an easy gardening container with the compression machine. Cut a hole in the tank’s side and use it as a container for flowers or vegetables in the garden. You can grow any kind of plant, including herbs like mint or vegetables like pumpkins and squash.

3. Prepare an aesthetic fire pit

Aesthetic things always attract us. How about turning the broken and lost compressor into a firepit? You can make the compressor tank into a fireproof, stylish fire pit. Let us know your creativity level by making art on the compressor! People have made amazing fire pits out of decommissioned tanks. It’s beautiful!

4. Sell the compressor or tanks metal parts

If you don’t want to keep your old compressor as a backup, go ahead and sell it! You can sell the entire compressor or the compressed air system machine metal parts to get some money, as metal parts have different levels of value. With a little money, you can purchase a new or second-hand compressor.

Don’t ditch anyone with a totally broken machine. Honesty is the best policy! So, when selling, make sure the machine can run after it has been fixed or repaired.

FAQs

1. Can you drive a car with a broken air compressor?

If you don’t use AC in your vehicle, you’ll be good to go with the car. Basically, the total effectiveness and safety depend on every part of the car. Therefore, driving is possible, but there is a risk because the compressor is damaged. It poses a serious risk to your health and the engine of your car.

2. Can I scrap air compressor?

If they meet the standards for scrap metal, compressors can be recycled for their value like scrap metal. Also, your compressors must be drained of free-flowing waste oil by the vehicle before they are recycled. Additionally, in the absence of an air ac compressor, you can use a hacksaw or Sawzall to scrap.

3. How do I get rid of air compressor?

If the problems are minor, you can quickly fix the compressor. For daily use, draining your compressor tank is excellent. This assists in releasing the moisture and residue that have formed inside the tank and reduces the corrosion process. Or, occasionally, you can look to see if there are any damages or problems to resolve the compressor issue.

4. How long does air compressor last?

According to SGS Engineers, reciprocating air compressors can last 10 to 15 years. A compressor system usually wears down when not properly maintained. You can retain it for a longer period of time if it is well maintained.

Final Words

In the concluding part, we can say there should be no issue regarding What To Do With Broken Air Compressor. We have fixed it properly or kept it as a backup plan, or we have shared some best ideas that you can use in the case of a damaged or broken compressor machine.

If you get confused about what to do with the compressed air machine, the best ideas should be our given tips. You won’t have to waste the machine. Rather, it can be used for your home’s purposes. As we said, make it a garden container, fire pit, or functional DIY smoker for the meats. Utilize the air compressor properly!